Roof working platforms

Customized to your needs

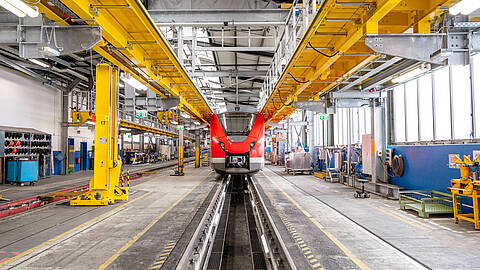

Roof working platforms are as diverse as the infrastructures in which they are used. Each of them is specially adapted to the task at hand and the local conditions.

The operating principles range from drawer constructions with various extension or folding systems to platforms that can be swivelled out to the side and mobile work platforms that move along the track. The electronic control of these systems plays a special role, as there are various dependencies between the drives and the safety edges as well as the connection of the overhead line and the access technology.

Employee safety takes centre stage in order to avoid endangerments as far as possible.

At the same time, robust mechanical engineering solutions ensure smooth operation, as the maintenance and inspection of modern trains and traction units place ever greater demands on throughput times in railway depots.

By developing different solutions, we not only build systems, but also provide our customers with advice and support. Take advantage of our experience!

Front fall protection

Safety has priority! The employees' work area extends to various areas on and around the vehicle. Especially when working on vehicles during repair or maintenance, it is important that employees are protected from falling. Blumenbecker frontal fall protection systems are used to provide the best possible protection for the working area.

A wide variety of designs are available. The operating principles range from side-hinged from one or both sides to gates that close from top to bottom, with the aim of individually securing the work area by closing the gap. Blumenbecker's front fall protection systems are made of steel or aluminium, depending on the customer's specifications and area of application.

When planning, we take into account the functionality of the roof working platform as well as the specified safetyregulations of our customers and find customised solutions.

Gap bridging

Work platforms have a fixed walkway. The vehicles being worked on are usually different in terms of model and dimensions. There is a gap between the work platform and the vehicle, which must be bridged for the safety of the employee.

Gap bridging systems from Blumenbecker are available in various designs:

With the flap element operating principle, the gap is bridged by a flap.

In the case of the drawer principle, the shoulder plates attached to the working platform are electrically extended to such an extent that they can be individually adjusted to the various widths of the vehicle.